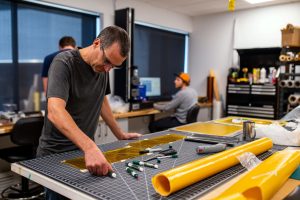

Material Scientists in the research and development lab at the Aluula Composites office in Victoria. Photo by James MacDonald

VICTORIA – Advanced materials technology firm ALUULA Composites is collaborating with the University of British Columbia to develop new recycling applications for the company’s composite materials.

ALUULA has developed a way to fuse high tech fibers and technical films together without the use of glues. With UBC Manufacturing Engineering students, the company is developing and refining applications on the uniform, lightweight and ultra-durable panels that ALUULA makes to exploit the inherent light and strong material properties but result in an end product that can be recycled again and again, thus lengthening the materials’ lifespan for years to come.

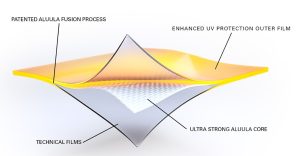

Composite materials are traditionally made by gluing together different core layers and outer films to create fabrics for use in a wide range of product applications. They are being used in products for windsports, sailing, outdoors and aerospace inventions.

“Working with UBC students on applications for these ultra-strong and ultra-durable products is proving to be invaluable as we refine our processes to ensure the recyclability of ALUULA materials.” says ALUULA Composites Material Scientist Sam White.

Diagram explains how ALUULA’s technology works

What makes the panels unique is that throughout the recycling process, the specialized fibres of the original ALUULA materials are kept intact. This results fibre reinforced composite panels that are 10 times stronger than those molded from virgin ultra-high molecular weight polyethylene (UHMWPE). From backpack back panels to low friction wear plates, the applications of these panels are suited to many tasks where strength, weight, abrasion resistance, and low friction are desirable.

“ALUULA has proven that sustainability and astounding performance can coexist without compromise. We look forward to leading the composite industry towards a more sustainable future,” says ALUULA Composites COO John Zimmerman.

ALUULA Composites Inc. composite materials are built from components with eight times the strength-to-weight ratio of steel, and yet lighter than nylon, polyester or aramid.

It’s the latest development for ALUULA, which announced a new generation of high-performance composite materials called Aeris and Aeris X at the end of July.

For example, the Aeris X introduces a proprietary X weave to the layup, providing additional reinforcement on the bias. The company says innovation leads to six-times higher bias strength, increased durability, superior UV resistance, and 6 times the tear resistance when compared to competing canopy and sail fabrics.

Aeris materials are made entirely from a single polymer, making them fully recycle-ready. In a further environmental initiative, ALUULA is creating logistics with brand and manufacturing partners to collect material off-cuts, and returning them via sea-freight to ALUULA in Canada. This makes it possible for offcuts to be re-processed into a new class of ALUULA fiber composite, which can also be recycled again, and again.

“Raising the bar by being ultra-lightweight and incredibly strong is one thing, but to deliver this performance while simultaneously introducing a much-needed greener trajectory for the future with these industry-first recycle-ready materials is knocking it out of the park,” says ALUULA CEO Richard Myerscough. “Since the beginning, our primary objective has been to create the ultimate performance composite fabric, breaking away from the dominance of single-use fabrics that have prevailed for far too long.”

ALUULA is a Canadian company, founded by a team of experienced chemists and engineers that share a common passion for exploring and enjoying the outdoors. ALUULA Composites strives to develop products and processes that are not hazardous to the environment and minimize the footprint they leave behind.

By Mark MacDonald