@crushdynamics.com

SUMMERLAND — The Canadian Food Innovation Network (CFIN) is awarding $1,984,274 to Crush Dynamics to develop and test a novel ingredient, created through upcycling, that will enhance food quality and drastically reduce sugar and sodium content in food products. The project is valued at just over $4M and is funded through CFIN’s Food Innovation Challenge Program.

Crush Dynamics’s project, Upcycling Agricultural Side Streams into High Performance Food Solutions Through Process Optimization, will be in partnership with Purdys Chocolatier and Ecovatec Solutions Inc.

Crush’s novel ingredient offers a path to improved nutrition and an ingredient the consumer understands and trusts for numerous applications across the food and beverage industry. Through partnership with Purdys, this project is opening global opportunities to reduce sugar content in chocolate. With the support of other collaborators like Ecovatec, Crush expects to bring this ingredient to market and accelerate adoption in the food and beverage sector.

“We are incredibly honoured to receive this support from the Canadian Food Innovation Network. Working with our partners, we look forward to advancing the state of the art in food formulation powered by polyphenols,” said Kirk Moir, CEO of Crush Dynamics.

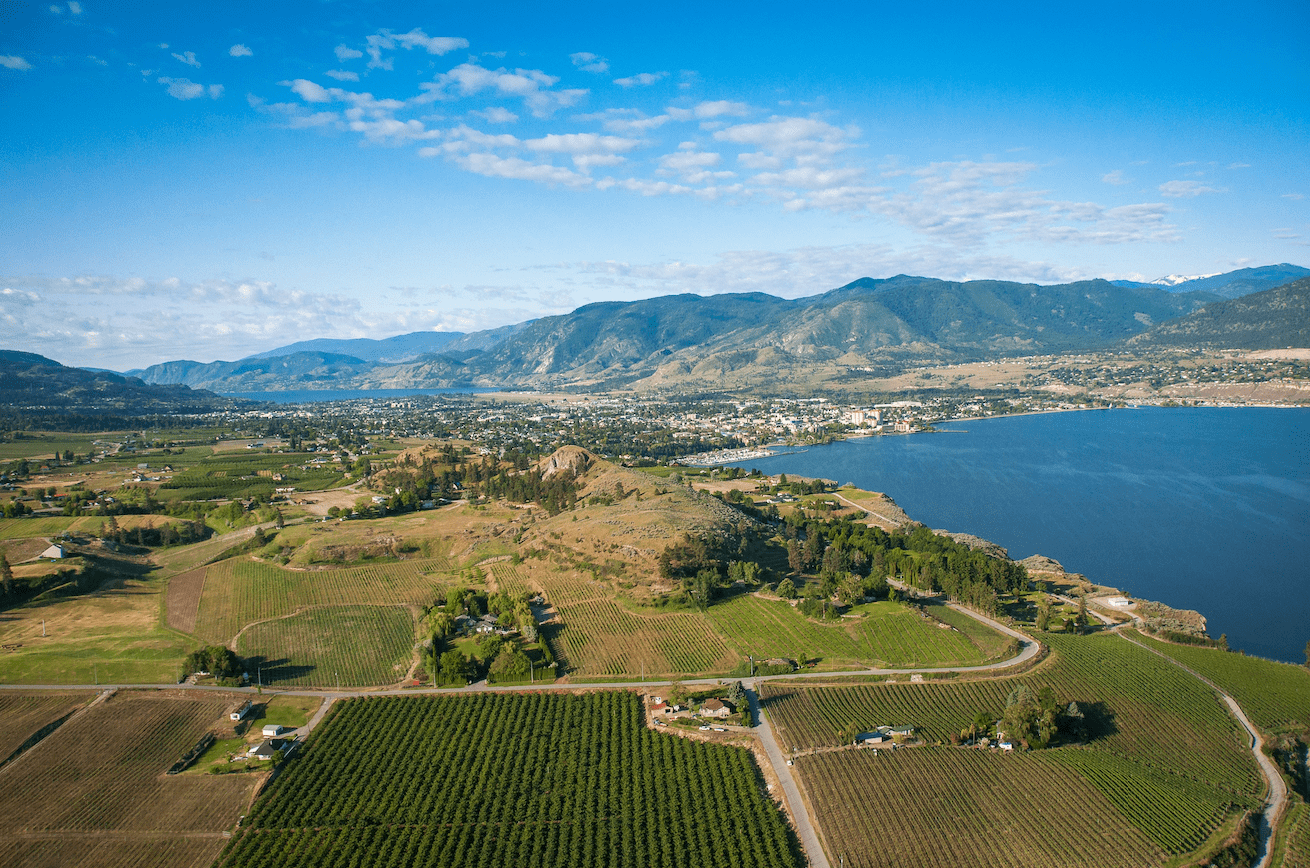

Crush Dynamics Inc. (Crush) leverages innovative fermentation of upcycled wine derivatives and agricultural waste to produce a proprietary, high-performance food ingredient. The resulting polyphenol-rich ingredient enhances food quality by enabling up to 50 per cent sugar reduction, 80 per cent sodium reduction, and improved texture while also extending shelf-life. This single ingredient provides food and beverage manufacturers with an opportunity to reduce complexity in their supply chain while delivering the clean label their consumers are demanding.

The project aims to demonstrate Crush’s production process at scale, from pre-processing treatments to fermentation and drying, employing automation to meet the demand forecasted by project partners and other potential customers. Through the fermentation of these waste products, Crush’s sustainable approach can help prevent up to 50 million tons of annual CO2 emissions that would otherwise result from the decomposition of these materials in landfills.

This funding call targeted disruptive solutions and innovative strategies for addressing food and beverage processing challenges. While the food and beverage manufacturing sector has seen strong growth over the last few years, it also faces many acute problems. Labour scarcity and inflationary pressures are constraining growth for many firms, despite continued strong consumer spending and the recession proof nature of the industry. Additional challenges like extending product shelf life, reducing energy consumption, and alleviating food waste are all hampering manufacturers as they strive to reduce costs and carbon footprints. As firms seek to grow amidst current market conditions, many are looking to optimize, automate, and increase the value of their products.

“Breakthrough innovation in the food and beverage industry is essential for addressing the pressing challenges faced by manufacturers. In the face of labor constraints, cost pressures, and sustainability imperatives, food innovation takes centre stage as the linchpin for overcoming obstacles and ensuring a resilient and forward-looking food sector,” said Dana McCauley, CEO of the Canadian Food Innovation Network

Since launching in 2021, CFIN has received more than 351 funding applications from innovative companies across the country and has approved $16.8M in funding to 51 projects.

Source: Canadian Food Innovation Network